Leading Manufacturers of Air Blast Coolers for Oil and Coolant Cooling

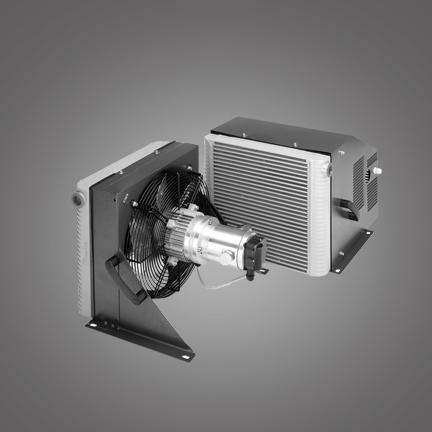

VARALKA Air Oil Coolers, constructed using bar and plate technology, are specially designed for oil, coolant and charge air cooling in industries and mobile vehicles and rail locomotives. Rugged and robust, our heat exchangers deliver under the most demanding operating environments.

Advantages of VARALKA Air Oil Coolers:

- Cooling elements, made from high-grade aluminium alloys

- Designed for use with a variety of hydraulic, transmission, lubricating and engine oils and water-glycol mixtures

- Light weight and compact size 2-3 times smaller than the copper tube and fin coolers

- Floating brazing junctions allow coolers to withstand pulsating oil flows

Oil side turbulators and airside fins are placed between aluminium braze sheets and fitted with long and short solid aluminium profiles. The assembled unit is then brazed with precise control of time and temperature. Thereafter hollow aluminium profiles are welded on both sides of this core, which serve as oil inlet and outlet manifolds. Our product portfolio offers multiple core depths, sizes, and fin densities to meet any application and system performance needs.

Offline Cooling Systems

These offline heat exchangers are designed to connect directly to the hydraulic reservoir. These coolers offer a reduced noise level while utilizing a pump driven by electric motor to automatically take the oil into circulation through the cooler and then return the oil back into the hydraulic circuit. This is a high efficiency and simple heat exchanger cooling system. Oil Filter can be incorporated as an additional component.

Varalka offline coolers are highly compact cooling systems especially useful for

- Gear Boxes

- Hydraulic Lifts

- Machine Tools

- Wind Mills

3 Models for heat transfer upto 15 kW are available. Models for higher heat dissipation and specific applications and features can be developed.

Traction Transformer Oil Coolers

Traction transformers in locomotives are designed to power heavy freight loads over long distances with many challenges – steep profiles, short curve radii, excessive wear, voltage drops in long sections, and extreme low and high temperatures, dry and rainy regions. Heat generated during its operation must be continuously dissipated for efficient and reliable operation of the transformer. Varalka designed and assembled transformer oil coolers are providing satisfactory service in various EMUs all over India.

These oil coolers are aluminium bar and plate design (also sometimes called plate fin type) and are light weight and rugged with high reliability. Welding of the cooling elements conforms to EN15085. Electric motor is certified and type tested IP67 protection and special winding wire.

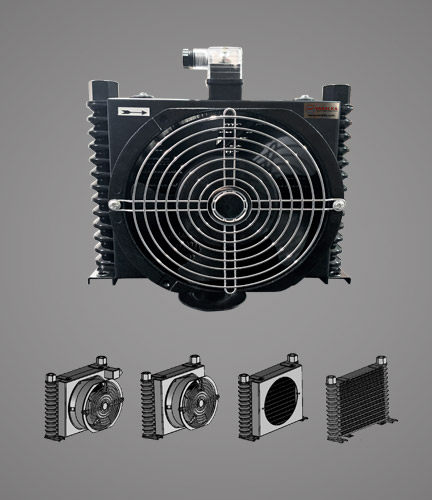

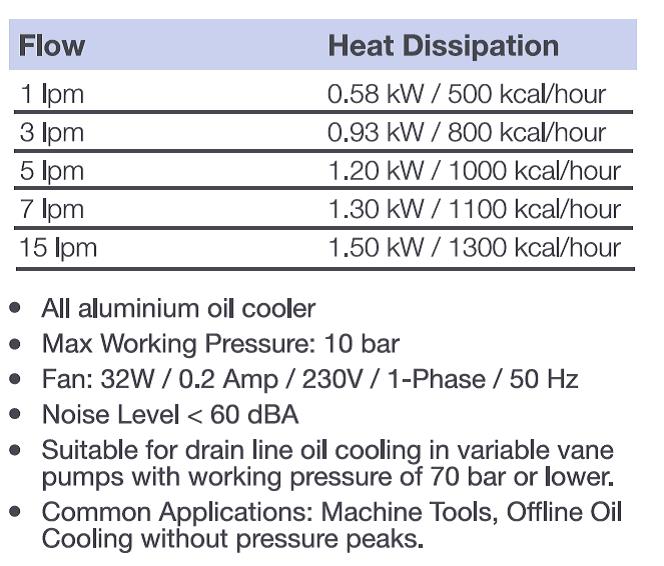

Drain Line Oil Coolers

Varalka is now the most preferred brand of drain line oil cooler in the Indian market with dominant market share. All leading manufacturers of machine tools and machine tools power packs use these coolers.

This is an all aluminium oil cooler Suitable for drain line oil cooling in variable vane pumps with working pressure of 70 bar or lower.

Applications

Air oil coolers can be used in several ways ranging from industrial to off highway to automobile to agriculture. Depending on the equipment used, air cooled heat exchangers are a great option to regulate the temperature of the equipment being used. Varalka air cooled heat exchangers find applications in a variety of industries, some of which are mentioned below. If you belong to any of the following industries, or if you otherwise require air cooled or water cooled heat exchangers / oil coolers for your application then get in touch with us.

- Hydraulic Oil Cooling and Lube Oil Coolers

- Combi Coolers for Mobile Vehicles

- Cone Crushers

- Cranes and Hydraulic Lifts

- Transformer Oil Coolers for Railways

- Converter Oil Coolers for Electric Locomotive

- Machine Tool Oil Coolers

- Transit Mixer Oil Coolers

- Compacters and Pavers

- Wagon Tipplers, Side Arm Chargers

- Wind Mills

- Gear Box Oil Coolers